ELECTRONICS SECTOR

The electricity and electronics sector relies on high-performance materials to ensure the safety, reliability and durability of equipment. The rapid growth of electrical infrastructure, smart grids, electronic devices and electric vehicles is driving ever-higher standards in thermal, electrical and acoustic insulation, while reducing environmental impact.

The global market for insulation materials for electronic and electrical components is estimated at ≈ $15 billion in 2025.

thumb_upGlobal leader in thermal, electrical and acoustic insulation solutions for electronics and automotive applications. Innovative and committed to sustainable materials.

tips_and_updatesPropose Fiberban™ as a natural, fire-retardant and recyclable material for insulating boards, electronic modules and cables. Highlight its technical performance and reduced carbon footprint.

thumb_upGlobal supplier of electrical and automation equipment, with a strong focus on safety and sustainability.

tips_and_updatesPresent Fiberban™ for transformers, inverters and electrical cabinets to improve thermal and fire insulation. Propose a pilot project on industrial installations.

thumb_upLeader in energy and industrial electronics solutions, with strong R&D and integration of innovative materials for critical components.

tips_and_updatesIntegrate Fiberban™ into control modules, electrical cabinets and embedded systems, highlighting its fireproof, thermal and anti-vibration properties. Propose an R&D collaboration to test Fiberban™ on their equipment.

The Fiberban™ patent covers the development and use of insulating and composite materials made from natural banana fibers for electrical and electronic applications.

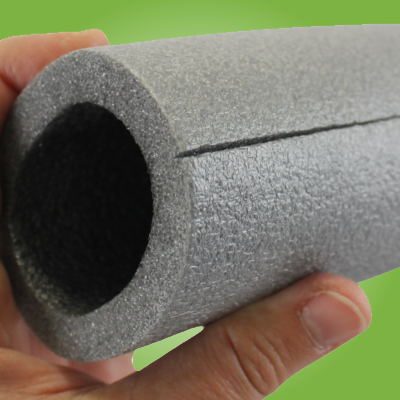

This innovative process involves the controlled transformation of banana fibers into biodegradable, thermally stable, and electrically resistant substrates, designed to replace conventional synthetic insulators.

The patented material demonstrates:

Target applications include eco-friendly printed circuit boards, insulating components, electronic housings, and natural thermal dissipation systems.

The Fiberban™ patent thus positions banana fiber as a sustainable technological solution at the core of next-generation green electronics.

Made from recycled non-hazardous waste, Fiberban™ helps to reduce the carbon footprint while recycling previously unused materials.

Made from recycled non-hazardous waste, Fiberban™ helps to reduce the carbon footprint while recycling previously unused materials. Effectively resists heat and fire, ensuring greater safety in buildings.

Effectively resists heat and fire, ensuring greater safety in buildings. Limits energy loss by providing excellent thermal insulation in both winter and summer.

Limits energy loss by providing excellent thermal insulation in both winter and summer. Reduces noise pollution, improving the acoustic comfort of interior spaces.

Reduces noise pollution, improving the acoustic comfort of interior spaces. Unlike asbestos, Fiberban™ is harmless to human health and has a long service life.

Unlike asbestos, Fiberban™ is harmless to human health and has a long service life.

Faced with increasing demands for sustainability, safety and performance in the defence sector, Fiberban™ is positioning itself as a strategic technology with strong potential.

Produced using a patented and sustainable process, this natural, fire-resistant, thermal and acoustic material has a variety of applications: insulation for military infrastructure, internal armouring, technical textiles, seals, adhesive surfaces and sensitive electronic systems.

*Gradual expansion and international adoption (2% of the market) approximately $15 billion in 2025 and is expected to reach $18.3 billion by 2030

Target segment: thermal, acoustic and fire insulation for electronic components, cables, batteries and electromechanical equipment

Global, non-exclusive

Royalty of revenue generated

Initial entry fee